ALKA S.r.l.

Sede legale: Via Teodoro Frizzoni 19 - 24121 Bergamo - Ufficio: Via Molino Baertsch, 4 - 24124 Bergamo

Tel. +39 035 664881, Cell. +39 335 355569 - E-mail: info@alka-srl.com , PEC postmaster@pec.alka-srl.com

Reg. Imprese di Bergamo, EORI, C.F e P.IVA IT02515810162 - Codice destinatario T04ZHR3

N° meccanografico BG050196, REA: BG 300962, Cap. Soc. €10.400,00 int. vers.

Effectiveness and solid experience

A solution dedicated to companies and professionals to clean tubes, hoses and pipings in various sectors.

With ALKA Pro-Clean you can degrease, lubricate and disinfect extremely efficiently, in a shorter time, for less money and using, only if necessary, minimum quantities of chemical products. You can also remove production scraps (e.g. from cutting, welding…). It can also be used for product recovery in the dosage tubes or as an instrument for regular maintenance and, last but not least, for quality control on new tubes.

Main advantages:

- Extremely fast and economic

- Ideal for quality control/selection of suppliers of new tubes

- Stronger cleaning power than techniques using compressed air or flushing

- Can be used for ordinary maintenance operations and prevention

- Can be used on curved tubes (even 90° bends), connectors, tees, ball valves, changes in diameter

- Can be used on rigid or flexible tubes and is compatible with any material

- You save a great deal on chemical products and consequently produce less waste

New tubes

For producers of new tubes (rods or coils), this system enables you to drastically increase the quality of the finished product since it can be used to remove shavings, soot, or product residue from pickling which, if not removed, leaves a greasy deposit at the bottom of the tube which is difficult to be removed subsequently, by the end customer, when it dries. Ideal for quality check upon supply.

Hydraulic - Pneumatic

In hydraulic systems it is very important not to have any kind of slag inside the circuit, even the smallest particles suspended in the oil can damage pumps, valves or cause a premature saturation of the filters. This system enables you to check and remove any residue traces in the tubes, from metal shavings to rubber dusts, enabling you also to verify the correct mix and vulcanization of the flexible hoses before using; this also contributes to speeding up the plant’s start up phase.

Automotive - Railway - Aero - Naval

Those are sectors where the interest is widely expressed, because each of these vehicles contains various devices that all work thanks to tubes of various kinds and these need to be extremely clean. From hydraulic and pneumatic movement systems to sanitary tubes, air conditioning systems, fuel injection tubes, braking systems, power steering, etc... This system enables you to carry out an accurate but fast quality control of the purchased tubes, ensuring an elevated and homogenous qualitative standard, obtaining maximum reliability and consequently maximum safety.

Food - Chemical - Pharma - Cosmetics

The main advantage in this field is the considerable reduction in waste, because you have the possibility to recover residue product at the end of the different production cycles before rinsing out. In this way it is possible to recover considerable quantities of good, sellable product and at the same time operate a mechanical pre-wash that effectively removes product residue stuck to the tube walls or in the system’s curves, which a simple fluid wash might not remove completely. The system can be used also for sanitization of tubes, by soaking the projectile with disinfectant products, combining thus mechanical and chemical action.

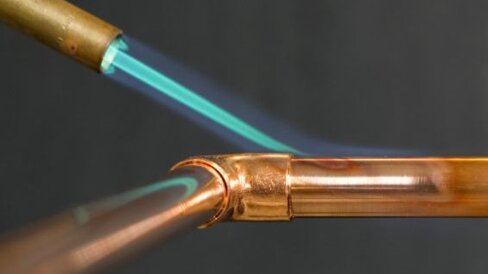

Clima - Piping - Technical gases

Before using new tubes, pipes or hoses, these may contain production residue such as grease or dusts that can contaminate the product flowing through them. Also dangerous fragments stuck to the inner walls are often not easily removed with just a rinse with fluids or compressed air, but only in subsequent phases to its use, damaging the more delicate components of the system.

It is also possible to carry out degreasing operations on piping for technical gases (oxygen, hydrogen, nitrogen, argon) or air conditioning.

Maintenance

There are numerous uses in maintenance that have proven to be incredibly useful and effective; depending on the kind of residue to remove you can obtain excellent results in the least time and at a cost that has no comparison with traditional techniques.

This applies to both general systems with tubes of various lengths that, for example, don’t need to be dismantled, as well as single components such as a tube bundle heat exchangers, especially if U shaped.